Key Neutron and X-ray Characterization Techniques

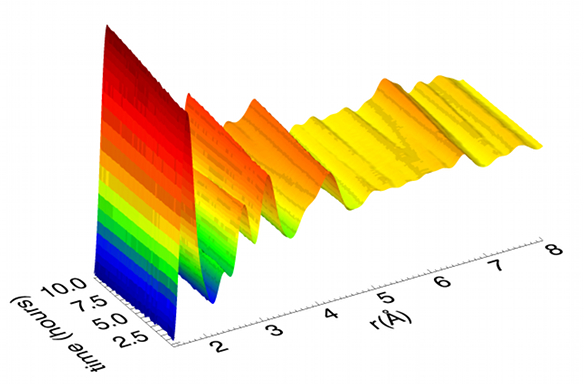

Total Scattering

For amorphous materials such as alternative cements and amorphous carbonate phases, conventional powder diffraction techniques yield limited information regarding their atomic bonding arrangements. Total scattering (which contains both Bragg [crystalline information] + diffuse [disorder information] scattering) is an experimental technique that is ideal for studying the atomic structure of disordered and amorphous materials. The requirements for a wide Q-range (scattering angle) and low and stable background have historically led to these experiments being conducted at spallation neutron sources and synchrotron facilities. However, due to recent developments in technology this type of analysis can now be performed on specialized laboratory X-ray diffraction instruments (typically with Mo or Ag radiation).

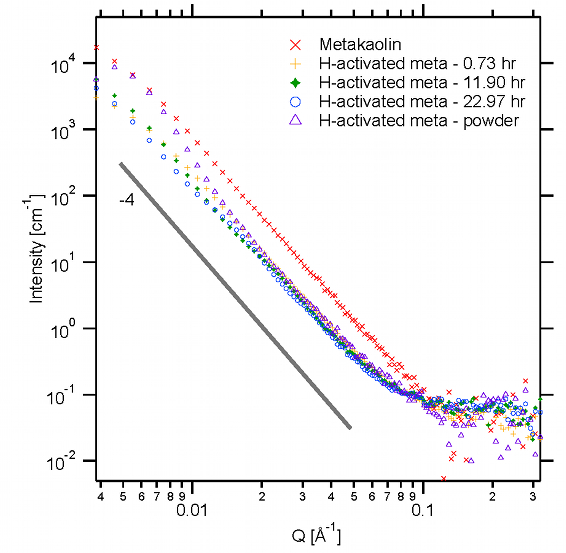

Small-Angle Scattering

Small-angle X-ray and/or neutron scattering provides information on the nanoscale morphology of materials and changes occurring over time. Applications for cements include in-situ measurements of the morphology changes occurring during formation and accurate density measurements. Neutron small-angle scattering enables contrast-matching (using hydrogen/deuterium) to pin-point information from solid, voids and surfaces within the material. More information can be found here.

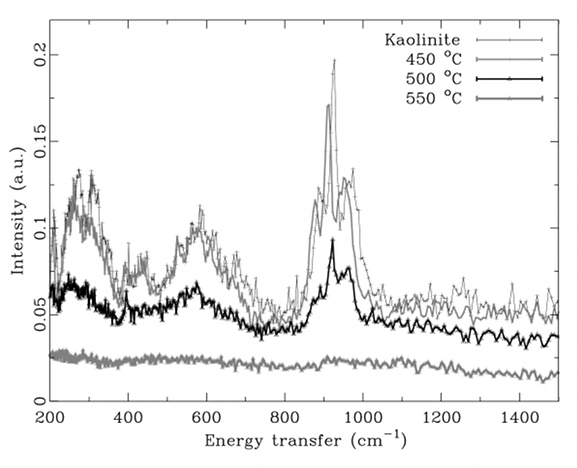

Inelastic Neutron Scattering

Discovering the role of water in cement systems and during CO2 storage is of importance for these technologies. Inelastic neutron scattering analysis is a key tool that can shed light on this area of research due to the large incoherent neutron scattering cross-section of hydrogen. By analyzing the vibrations of hydrogen in the materials, the location and bonding of H-atoms can be elucidated. Once the role of water is discovered for these systems, the materials can be optimized to obtain superior properties and performance characteristics. Read more about inelastic neutron scattering here at the ISIS webpage.

Micro- and Nano-Tomography

X-ray micro- and nano-tomography are two techniques used to probe the micro- and nano-scale morphology of materials. Micro-tomography is used as a non-destructive technique to analyze the pore structure of alkali-activated cements, extracting out key parameters including porosity and tortuosity. Nano-tomography is used to study the binder phase of the cement gels at the nanoscale. When combined with fluorescence, nano-tomography can resolve the spatial distribution of elements in the cement binders and other materials. The wikipedia page for micro-tomography can be found here. X-ray nano-tomography is available at the nanoprobe beam line at the Advanced Photon Source and other synchrotron facilities around the world.

Some Laboratory Experimental Tools

X-ray Powder Diffraction

Identification and quantification of crystalline phases present in composite materials can be carried out using laboratory-based X-ray powder diffraction. This standard form of analysis is a component of research for alkali-activated materials and associated systems.

Beam bending

SCG has two beam-bending instruments capable to measuring the permeability and creep of porous viscoelastic materials. This technique was recently applied to alkali-activated slag pastes for the first time.

Thermal Analysis

One experimental tool capable of quantifying the amount and type of water in a sample (i.e, bound vs. free water) is thermogravimetric analysis (TGA). This is achieved by measuring the weight loss of a sample as a function of temperature. Among other things, TGA is also used to measure weight changes associated with decomposition or oxidation of a material. Complementary thermal analysis instruments include thermal mechanical analysis (TMA), which measures changes in dimensions and/or mechanical properties as a function of temperature, and differential scanning calorimetry (DSC), which measures heat gain/loss of a sample (endothermic vs. exothermic) as a function of temperature.

Mechanical Testing

Without the compressive strength characteristics of concrete, this material would not be used as extensively throughout the world as it is today. However, understanding which mix designs provide superior compressive strength and associated mechanical properties is a necessary component of cement materials research. Other testing methods that are necessary include creep and fatigue.